-

Collagen

-

Type I - Atelocollagen

- PureCol® Solution, 3 mg/ml (bovine) #5005

- Nutragen® Solution, 6 mg/ml (bovine) #5010

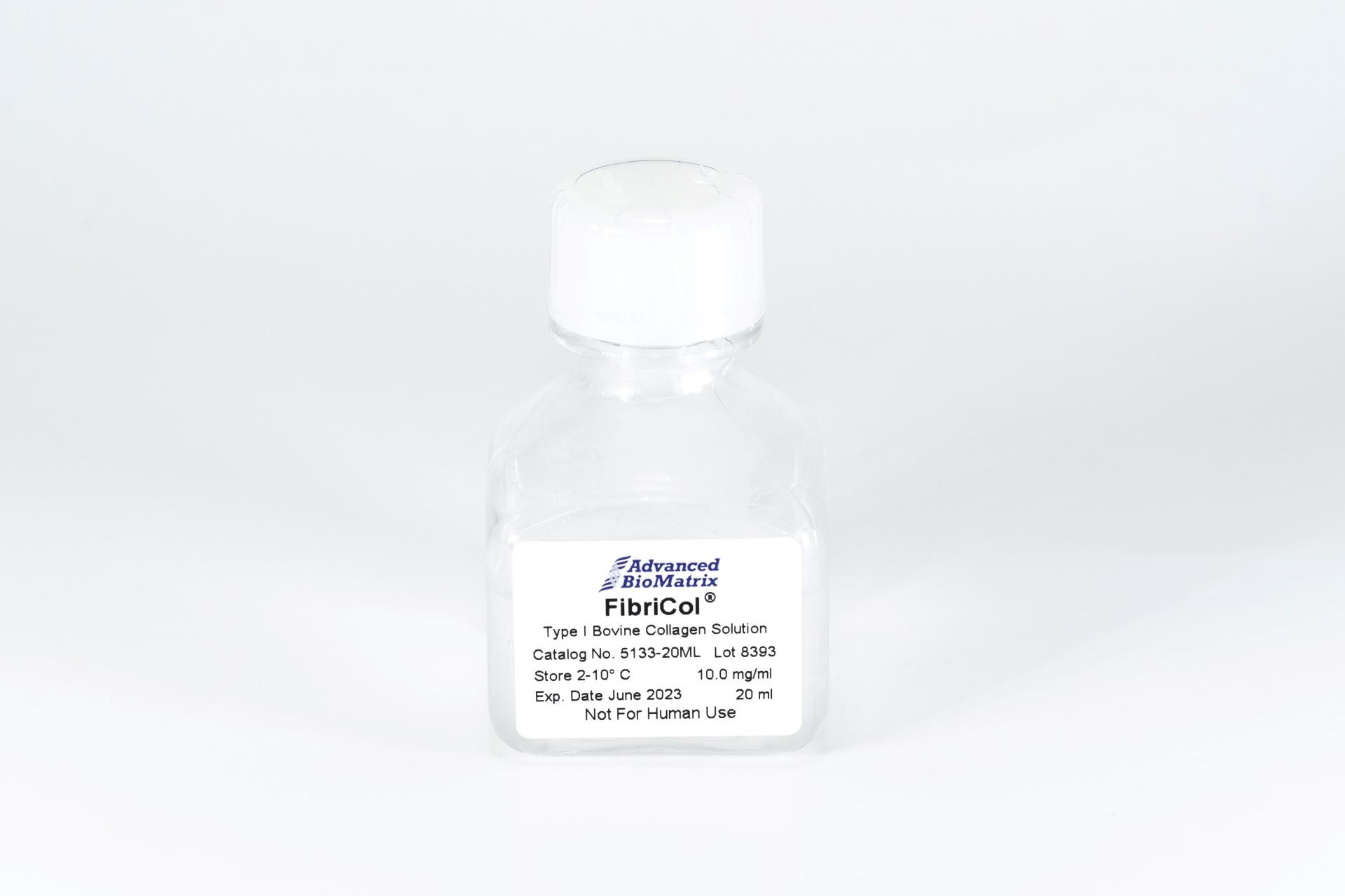

- FibriCol® Solution, 10 mg/ml (bovine) #5133

- PureCol® EZ Gel, Solution, 5 mg/ml (bovine) #5074

- PureCol® Lyophilized, 15 mg (bovine) #5006

- VitroCol® Solution, 3 mg/ml (human) #5007

- VitroCol® Lyophilized, 15 mg (human) #5008

-

Type I - Telocollagen

- TeloCol®-3 Solution, 3 mg/ml (bovine) #5026

- TeloCol®-6 Solution, 6 mg/ml (bovine) #5225

- TeloCol®-10 Solution, 10 mg/ml (bovine) #5226

- RatCol™ for 2D and 3D, Solution, 4 mg/ml (rat) #5153

- RatCol™ High Concentration, Solution, 10 mg/ml (rat)

- RatCol™ lyophilized, 100 mg (rat)

- RatCol™ for Coatings, Solution, 4 mg/ml (rat) #5056

- Type I - Insoluble Collagen

- Type I - Bioinks

- Type II Collagen

- Type III Collagen

- Type IV Collagen

- Collagen Standard

-

PureCol® Collagen Coated Plates

- Collagen Coated T-25 Flasks #5029

- Collagen Coated 6-well Plates #5073

- Collagen Coated 12-well Plates #5439

- Collagen Coated 24-well Plates #5440

- Collagen Coated 48-well Plates #5181

- Collagen Coated 96-well Plates #5072

- Collagen Coated 384-well Plates #5380-5EA

- Collagen Coated 100 x 20 mm Dishes #5028

- MatTek Glass-Bottom Dishes

- MatTek Multi-Well Plates

- Collagen Scaffolds

- Collagen Hybridizing Peptides

-

Type I - Atelocollagen

- Tunable Stiffness

- CytoSoft™ Rigidity Plates

-

Bioprinting

- Support Slurry for FRESH Bioprinting

-

Bioinks for Extrusion Bioprinting

- Lifeink® 200 Collagen Bioink (35 mg/ml) #5278

- Lifeink® 220 Collagen Bioink (70 mg/ml) #5343

- Lifeink® 240 Acidic Collagen Bioink (35 mg/ml) #5267

- Lifeink® 260 Acidic Collagen Bioink (70 mg/ml) #5358

- GelMA Bioink

- GelMA A Bioink

- GelMA C Bioink

- Pluronic F-127 40% Sterile Solution

- GelMA 20% Sterile Solution

- Alginate 5% Sterile Solution

- Photoinitiators

- Bioinks for BIONOVA X

- Bioinks for Lumen X

- DLP Printing Consumables

-

Create Your Own Bioinks

- PhotoCol® Methacrylated Collagen

- PhotoGel® Methacrylated Gelatin 95% DS

- PhotoGel® Methacrylated Gelatin 50% DS

- PhotoHA®-Stiff Methacrylated Hyaluronic Acid

- PhotoHA®-Soft Methacrylated Hyaluronic Acid

- PhotoAlginate® Methacrylated Alginate

- PhotoDextran® Methacrylated Dextran

- PEGDA (Various Molecular Weights)

- Silk Fibroin, Solution

- PhotoSericin® Methacrylated Sericin

- Bioprinters

-

3D Hydrogels

- Thermoreversible Hydrogel

- Silk Fibroin

-

Type I Collagen for 3D Hydrogels

- PureCol® Solution, 3 mg/ml (bovine) #5005

- Nutragen® Solution, 6 mg/ml (bovine) #5010

- FibriCol® Solution, 10 mg/ml (bovine) #5133

- PureCol® EZ Gel, Solution, 5 mg/ml (bovine) #5074

- VitroCol® Solution, 3 mg/ml (human) #5007

- TeloCol®-3 Solution, 3 mg/ml (bovine) #5026

- TeloCol®-6 Solution, 6 mg/ml (bovine) #5225

- TeloCol®-10 Solution, 10 mg/ml (bovine) #5226

- RatCol® for 3D gels, Solution, 4 mg/ml (rat) #5153

- HyStem® Thiolated Hyaluronic Acid

- Methacrylated Collagen

- Methacrylated Gelatin

- Methacrylated Hyaluronic Acid

- Diacrylates

- Collagen Sponges

- Methacrylated Polysaccharides

- Spheroids and Organoids

- Extracellular Matrices

- HyStem / Hyaluronic Acid

-

Adhesion Peptides / Proteins

-

Recombinant Adhesion Proteins

- CD2, 0.5 mg/ml #5086

- CDH3, 0.5 mg/ml #5124

- CDH13, 0.5 mg/ml #5125

- CD14, 0.5 mg/ml #5089

- CDH18, 0.5 mg/ml #5090

- CD40, 0.5 mg/ml #5093

- CD86, 0.5 mg/ml #5096

- CD164, 0.5 mg/ml #5100

- CD270, 0.5 mg/ml #5127

- CD274, 0.5 mg/ml #5126

- CD276, 0.5 mg/ml #5123

- E-Cadherin (CD324), 0.5 mg/ml #5085

- ICAM2, 0.5 mg/ml #5107

- Adhesion Peptides

- Collagen Hybridizing Peptides

-

Recombinant Adhesion Proteins

- Reagents

- Assays

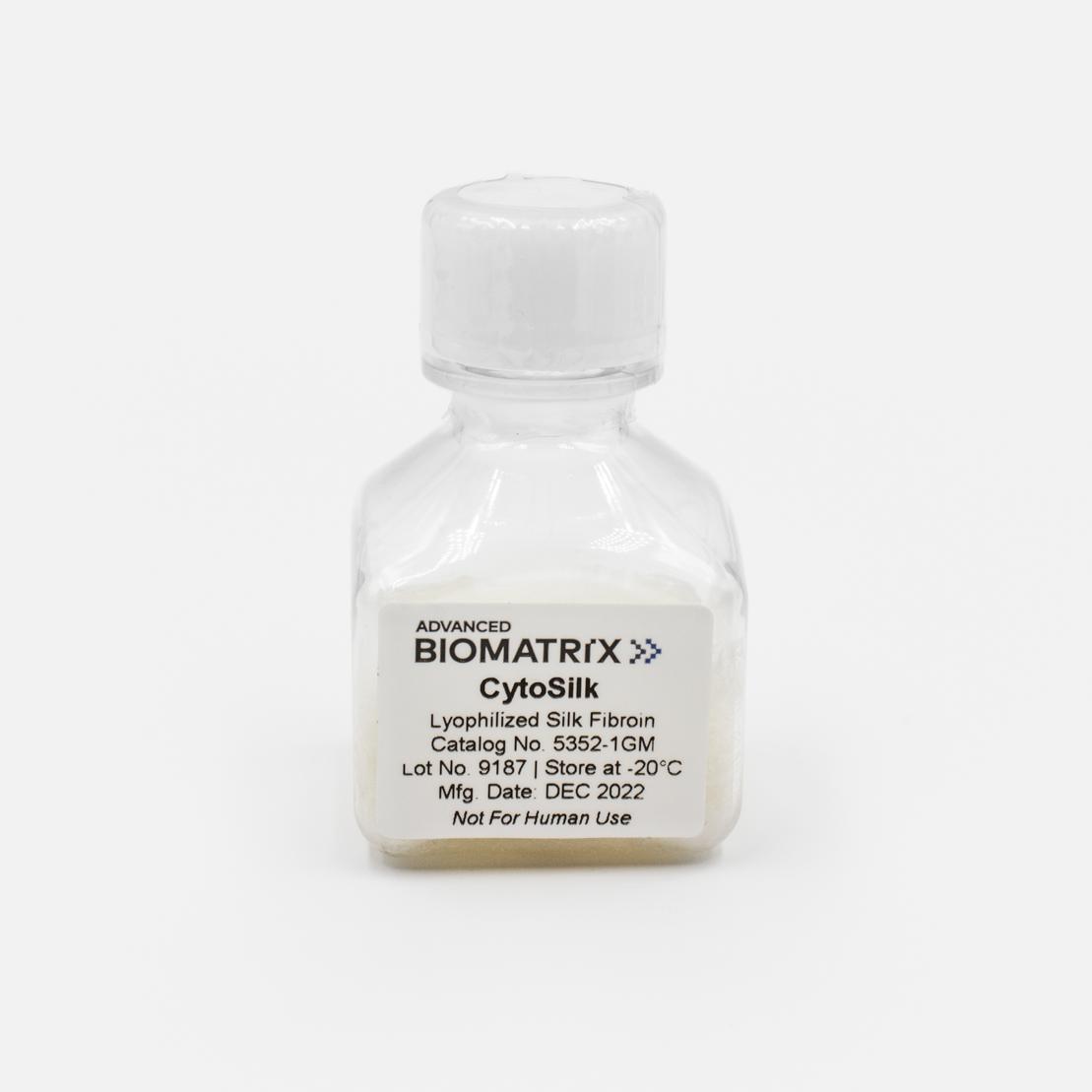

CytoSilk Silk Fibroin

Powder, 1 gram

Catalog #5352

CytoSilk Silk Fibroin

Powder, 1 gram

Catalog #5352

This Silk Fibroin lyophilized powder is approximately 1 gram of lyophilized protein derived from the Bombyx Mori silkworm. Silk Fibroin can be reconstituted at various concentrations and is useful for forming various scaffolds such as coatings, films, sponges, hydrogels and electrospun fibers.

Product Description

Advanced BioMatrix’s lyophilized silk fibroin is approximately 1 gram of protein with a molecular weight of approximately 100k Da and can be reconstituted between 1-10% wt/v in water. The silk solution is made of 100% fibroin protein that is derived from the domesticated Bombyx mori silkworm. The product is manufactured in a manner to minimize contamination and has a low bioburden but is not considered sterile.

Fibroin protein is the major structural component of the silkworm’s cocoon fiber. Fibroin offers great potential for use in medically related applications due to the high degree of biocompatibility and lack of immune response when implanted within the body. The silk fiber is solubilized into an aqueous fibroin solution, which can then be used as an additive in culture or for producing 3D scaffolds for tissue-engineering related studies.

As with traditional tissue-engineering approaches, the silk scaffolds are typically seeded in vitro with a specific cell type as most cells will adhere to fibroin protein, and then cultured over time to mimic tissue architecture. It has been shown that the silk fibroin protein can be degraded a number of naturally occurring proteolytic enzymes, and is thus a biologically active scaffold unlike other synthetic materials. As a result the silk scaffold material is degraded and remodeled through similar physiological pathways in the body. Silk fibroin protein is composed of both non-essential and essential amino acids, with a particular concentration of alanine and glycine present, and these amino acids are then reabsorbed by the surrounding cells for new tissue regeneration. This is important as silk degradation products do not collect in the local environment to induce a toxicity which is commonly associated with other synthetic and naturally occurring biomaterials.

The ability to produce a variety of forms and formats scaffold types (e.g. coatings, films, sponges, hydrogels, electro-spun fibers, micro/nanospheres, etc.) offers a number of advantages over other biopolymer systems like collagen, chitosan, and alginate that have less variety in processing choices. The silk material properties can then be modified through a variety of processing techniques to change degradation rate, hydrophobicity/hydrophilicity, transparency, mechanical strength, porosity, oxygen permeability, and thermal stability. In this regard, silk proteins represent a class of biopolymers with definable material properties for a given application.

This product is prepared from silk fibroin extracted from Bombyx mori silkworm cocoons and contains a high monomer content with a molecular weight of approximately 100k Da.This product is aseptically processed resulting in a low bioburden but is not considered sterile. If culturing cells using this product, measures should be taken to maintain sterility of cultures such as use of antibiotics. This product is shipped separately on dry ice.

| Parameter, Testing, and Method | Silk Fibroin #5352 |

| Form | Lyophilized Powder |

| Package Size | 1 gram |

| Storage Temperature | -20°C |

| Shelf Life | Minimum of 6 months from date of receipt |

| Purity - SDS PAGE Electrophoresis | Characteristic |

| pH | >4.5 |

| Bioburden | Low (< 50 CFU's) but not sterile |

| Cell Culture Conditions | Antibiotics are recommended |

| Endotoxin | < 5.0 EU/mL |

| Source | Domesticated Bombyx Mori Silkworm |

| Osmolality (mOsmo H20/kg) | <160 |

| Molecular Weight (kDa) | 100-150 |

Directions for Use

Download the full PDF version or continue reading below:

Experimental Protocols for Material Processing :

Prior to following the protocols below, it is recommended to reconstitute the Silk Fibroin at a concentration of 1-10% with cold, sterile water. Most protocols below are designed for 5% Silk Fibroin solutions.

1. Culture Well Coating Procedure: Use these recommendations as guidelines to determine the optimal coating conditions for your culture system.

- Remove required quantity of silk solution from the bottle and dispense into a dilution vessel.

- Dilute silk solution with water to 1 mg/mL (1:50).

- Swirl contents gently until material is completely mixed.

- Add appropriate amount of diluted silk solution to the culture surface ensuring that the entire surface is coated.

- Incubate in a clean bench (ISO 100) at room temperature uncovered, for 2-3 hours to allow for complete drying.

- After incubation apply 70% methanol for 20 minutes to induce a water-insoluble silk surface.

- Rinse coated surfaces carefully with sterile medium or PBS. Do not scratch surface.

- Coated surfaces are ready for use or may be stored at 4°C for future use.

2. Concentrating Silk Solution: This technique is used if a higher silk concentration is desired. Higher silk concentrations may be important for specific processing techniques or to modify final material properties.

- Prepare a 10% (W/V). solution of polyethylene glycol (PEG, 10K MW) with deionized water. Mix with a large stir bar on a magnetic stir plate until PEG is completely dissolved.

- Obtain a dialysis membrane with a molecular weight cutoff between 3,500 and 10,000 Da. If necessary hydrate the dialysis cassette per the manufacturer requirements.

- Fill the dialysis membrane with the appropriate amount of 5% silk solution per the dialysis membrane manufacturer guidelines for filling volume.

- Place the silk solution filled dialysis membrane into the 10% (wt/vol) PEG solution and cover.

- Indicate the time and date that the cassette was added to solution. Typical concentrating times will vary depending on the desired final concentration of silk solution, the volume of silk solution being concentrated, and the dialysis membrane used.

Note As a typical example, 10 mL of 5% silk solution will yield 2–4 mL of concentrated silk solution after dialyzing against 10% (W/V) PEG for 20–22 hours. In general, optimization runs are usually recommended per user requirements. - Remove the concentrated silk solution from the PEG bath and dialysis cassette after the concentrating time has finished and store silk solution at 4°C for future use. NOTE: Silk solution shelf life decreases with increasing concentration, so use concentrated silk solution soon within 1 week after it is produced.

- Silk solution concentration can be determined by weight percent concentration. To do this, weigh out approximately 100 µL of concentrated silk solution on a precision balance and record the wet weight. Allow the solution to dry into a film and measure the silk protein dry weight. Divide the dry weight over the wet weight and multiply by 100% to get the weight percent concentration of the solution.

3. Freestanding Silk Films: This processing method produces freestanding silk film materials that can be used for cell culture or in vivo transplantation. Freestanding silk films offer the advantage of easy removal from culture conditions for further sample analysis.

- Add 7 mL of 5% silk solution into a 100 mm Petri dish and allow drying uncovered in a clean bench environment. This typically takes several hours and is best left overnight.

- The formed film will be approximately 40-60 µm in thickness and can be removed from the Petri dish using forceps. Increasing the amount of silk solution or using higher concentration silk solution produces thicker films.

- The films are currently water-soluble and can be made insoluble for cell culture using either of the following methods:

i. Methanol bath incubation:

a. Fill dish with 70% methanol and 30% deionized water and mix.

b. Place silk film into methanol solution for 10 minutes.

c. Remove silk film and rinse with sterile water or appropriate medium.

Note : This processing method rapidly produces insoluble silk film material properties that tend to be opaque, more hydrophobic, and have slow degradation rates in situ.

ii. Water-annealing:

a. Obtain an emptied lab vacuum desiccator and fill bottom partially with water.

b. Place films on shelf above water, cover, and then pull a 25 in Hg vacuum.

c. Stop cock the chamber and allow to sit for 4 hours.

d. Remove samples from chamber and sterilize with 70% ethanol and then rinse with sterile water or appropriate media.

Note: This processing method produces insoluble silk film material properties that tend to be transparent, more hydrophilic, and have fast degradation rates in situ.

- Films can then be cut to shape and stored for 2 years or more at room temperature if not used immediately.

Note: Silk films can also be cast onto patterned surfaces to replicate the surface topography, typically silicone rubber or similar materials will be used for ease of silk material removal. In addition, weighting methods may be required to keep films submerged in media due to potential material buoyancy.

4. 3D Silk Sponge Scaffolds: This processing method creates 3D porous scaffolds for both in vitro and in vivo applications or in situ implantation. The scaffold pore size and degradability characteristics can also be tuned using the method below.

A. Aliquot silk solution into a desired molding vessel, Teflon is recommended to allow for ease of material removal.

B. For each sample being prepared weigh the necessary amount of salt to maintain a 25:1 ratio of salt to silk weigh.

Note: The control over pore size is dictated by the chosen sodium chloride (salt) crystal size. If a defined pore size is preferred use stainless steel sieves to produce a uniform salt crystal size. It is recommended for salt particles that are 750 µm and larger that the silk solution is concentrated to 8% or above.

C. Add the salt slowly to the silk solution while rotating the molds to allow for uniform salt addition. Be sure to carefully remove air bubbles formed from material displacement through mild agitation or tapping on a surface.

D. Cover the mold and allow the solution to sit for 1-2 days at room temperature to allow for silk scaffold formation.

E. After the scaffold has formed remove the mold cover and place samples into a 2-liter beaker of DI water and place on stir plate.

F. Change the water every 8-12 hours for 48 hours.

H. After the washing period remove the formed scaffolds from the mold and place in a final deionized water rinse for 24 hours to ensure complete removal of residual salt.

I. Scaffolds can be stored in deionized water for at 4 °C or dry at room temperature until needed.

J. The scaffolds can be cut to the required dimensions and steam sterilized before using

5. 3D Silk Hydrogels: This processing method can be used to produce silk hydrogels for use as an injectable biomaterial, in vitro culture, and in vivo use.

A. Place the 5% silk solution into the desired molding vessel or vial.

B. Secure the vessel or vial to a lab vortexer with tape in an upright position.

C. Vortex the solution for a several minutes and at maximal rotational speed. These parameters will need to be optimized for the given silk solution volume and mold geometry.

Note: As an example, pipette 1 mL of silk solution in a glass vial and vortex for ~7 min at 3,200 RPM. The solution should increase in turbidity indicating the gelation process has been initiated.

Note: Once the solution has been vortexed, do not transfer the solution to a secondary container before gelation has completed.

D. Place the vortexed silk/molding vessel/vial in a 37 °C incubator overnight to expedite gelation time.

E. Silk hydrogels can be used for future use as long as they remain hydrated and stored in deionized water at 4 °C.

Product Q & A

The silk fibroin contains a fair number of aspartic (0.5 mol%, ~25 residues) and glutamic acids (0.6 mol%, ~30 residues),as well as a small number of lysine residues (0.2 mol%, ~12 residues).

We use the dry down method. (Weigh out a certain amount of silk fibroin and leave in a 60C oven overnight, and weigh the left-over protein).

The silk we supply is a partially hydrolyzed silk fibroin II solution. Whole cocoons, harvested from domesticated Bombyx mori in China, are degummed and processed into a liquid protein solution using heavy inorganic salts. The solution is then desalted, tested, and packaged. One of the key features of our silk fibroin solution is the preservation of the fibroin light chain at around 25 kDa as shown on the gel.

Prepare 1- 2 Liters of 10% wt./vol. PEG solution and then dialyze the 5% fibroin solution overnight in a 3 kDa dialysis cassette overnight (~12 hrs). This should get you to between 10% - 15% fibroin.

Otherwise, the 'quick and dirty' way to do this is allow the water to evaporate from the Silk Fibroin 5% solution in a clean bench. You can dispense the Silk Fibroin solution into a large weigh dish to increase the evaporative surface and then check the dry weight of the fibroin protein periodically. This method can concentrate the solution significantly by the end of the work day.

The Silk Fibroin Protein that we offer is in the ‘regenerated’ form. This material is derived from the silk worm cocoon and then processed and solubilized into an aqueous form.

The silk is a partially hydrolyzed solution of fibroin heavy and light chain proteins. There will be some free amino acids present due to this hydrolysis, but the large majority of the material consists of the former two elements (heavy and light chains).

The silk solution is made from de-sericinized (or degummed it is sometime called) silk fiber. We remove the sericin via our extraction process.

Yes.

A coating allowed to air dry, or a shorter (15-30 minutes) water annealing.

While the native fibroin proteins exist in a 6:6:1 ratio, this composition is almost certainly not preserved during the manufacturing process that are used to create aqueous fibroin solution. This is because the heavy and light chains of fibroin have considerably different amino acid composition and hydrophobicity, rendering them unequally prone to hydrolysis during sericin degumming. This can be seen on the electrophoretic gel from the solution, where the heavy chain is seen as a smear, but the light chain is a relatively preserved band. We have not endeavored into determining the extent of p25 hydrolysis.

Yes.

It is best to maintain the product at -70 C. Any unused solution should be divided into smaller aliquots and frozen. Try to thaw/refreeze as few times as possible.

The 5% solution has a viscosity of ~12cp. When diluted in water to 2.5%, the viscosity is ~6cp.

Yes, overmixing can alter the physical properties of the solution, the solution is sensitive to mechanical stresses such as shear force. For example, it is possible to induce gelation of the Silk Fibroin Solution by simply vortexing it for 10-15 minutes. Aliquoting the solution or more gentle mixing processes would help reduce changes to the bulk solution.

Lyophilization is not recommended. Unfortunately lyophilization will drive irreversible beta sheet formation under standard conditions.

Fibroin can typically be reconstituted to around 20% protein before it starts to crash out of solution.

If your Silk Fibroin has been stored at a temperature warmer than -20C for too long, it may form aggregates. Unfortunately, due to the tight binding nature of beta-sheets, it is very difficult to redissolve aggregates. We have also tried using LiBr, which was unsuccessful.

No - it is all protein/amino acid.

Yes. The results can be found here.

The silk backbone itself is enzymatically degradable, so some sort of cocktail with high concentration proteinase K should do the work.

Product References

References using Silk Fibroin from Advanced BioMatrix

Compaan, Ashley M., Kyle Christensen, and Yong Huang. "Inkjet bioprinting of 3D silk fibroin cellular constructs using sacrificial alginate." ACS Biomaterials Science & Engineering8 (2016): 1519-1526.

Jiang, Bojing, et al. "Water‐Based Photo‐and Electron‐Beam Lithography Using Egg White as a Resist." Advanced Materials Interfaces7 (2017): 1601223.

Liew, Lawrence J., Richard M. Day, and Rodney J. Dilley. "Tympanic membrane organ culture using cell culture well inserts engrafted with tympanic membrane tissue explants." BioTechniques3 (2017): 109-114.

Jativa, Fernando, and Xuehua Zhang. "Transparent silk fibroin microspheres from controlled droplet dissolution in a binary solution." Langmuir31 (2017): 7780-7787.

Maghdouri-White, Yas, et al. "Mammary epithelial cell adhesion, viability, and infiltration on blended or coated silk fibroin–collagen type I electrospun scaffolds." Materials Science and Engineering: C43 (2014): 37-44.

Choi, Moonhyun, Daheui Choi, and Jinkee Hong. "Multilayered controlled drug release silk fibroin nano-film by manipulating secondary structure." Biomacromolecules(2018).

Other references using Silk Fibroin:

Panilaitis B, Altman G, Chen J, Jin H, Karageorgiou V, Kaplan D. Macrophage responses to silk. Biomaterials. 2003;24(18):3079–85.

Meinel L, Hofmann S, Karageorgiou V, Kirker-Head C, McCool J, Gronowicz G, et al. The inflammatory responses to silk films in vitro and in vivo. Biomaterials. 2005;26(2):147–55.

Wang Y, Rudym D, Walsh A, Abrahamsen L, Kim H, Kim H, et al. In vivo degradation of three-dimensional silk fibroin scaffolds. Biomaterials. 2008;29(24-25):3415–28.

Kim U, Park J, Kim HJ, Wada M. Three-dimensional aqueous-derived biomaterial scaffolds from silk fibroin. Biomaterials. 2005.

Horan R, Antle K, Collette A, Wang Y, Huang J, Moreau J, et al. In vitro degradation of silk fibroin. Biomaterials. 2005;26(17):3385–93.

Li M, Ogiso M, Minoura N. Enzymatic degradation behavior of porous silk fibroin sheets. Biomaterials. 2003;24(2):357–65.

Desjardins M. Phagocytosis: at the crossroads of innate and adaptive immunity. Annu Rev Cell Dev Biol. 2005.

Onuki Y, Bhardwaj U. A review of the biocompatibility of implantable devices: current challenges to overcome foreign body response. J Diabetes Science and Technology. 2008.

Motta A, Fambri L, Migliaresi C. Regenerated silk fibroin films: thermal and dynamic mechanical analysis. Macromolecular Chemistry and Physics. 2002;203(10-11):1658–65.

Agarwal N, Hoagland D, Farris R. Effect of moisture absorption on the thermal properties of Bombyx mori silk fibroin films. Journal of Applied Polymer Science. 1997;63(3):401–10.

Jin H, Park J, Valluzzi R, Cebe P, Kaplan D. Biomaterial films of Bombyx mori silk fibroin with poly (ethylene oxide). Biomacromolecules. 2004;5(3):711–7.

Tretinnikov O, Tamada Y. Influence of casting temperature on the near-surface structure and wettability of cast silk fibroin films. Langmuir. 2001;17(23):7406–13.

DuFort CC, Paszek MJ, Weaver VM. Balancing forces: architectural control of mechanotransduction. Nat Rev Mol Cell Biol. Nature Publishing Group; 2011 May;12(5):308–19.

Califano JP, Reinhart-King CA. A Balance of Substrate Mechanics and Matrix Chemistry Regulates Endothelial Cell Network Assembly. Cel Mol Bioeng. 2008 Oct 15;1(2-3):122–32.

Reinhart-King CA. How Matrix Properties Control the Self-Assembly and Maintenance of Tissues. Annals of Biomedical Engineering. 2011 Apr 14;39(7):1849–56.

Rice W, Firdous S, Gupta S, Hunter M, Foo C, Wang Y, et al. Non-invasive characterization of structure and morphology of silk fibroin biomaterials using non-linear microscopy. Biomaterials. 2008;29(13):2015–24.

Lawrence BD, Pan Z, Weber MD, Kaplan DL, Rosenblatt MI. Silk film culture system for in vitro analysis and biomaterial design. J Vis Exp. 2012;(62):e3646.

Lawrence B, Cronin-Golomb M, Georgakoudi I, Kaplan D, Omenetto F. Bioactive silk protein biomaterial systems for optical devices. Biomacromolecules. 2008;9(4):1214–20.

Omenetto F, Kaplan D. A new route for silk. Nature Photonics. 2008;2(11):641–3.

Rockwood DN, Preda RC, Yücel T, Wang X, Lovett ML, Kaplan DL. Materials fabrication from Bombyx mori silk fibroin. Nature protocols. Nature Publishing Group; 2011;6(10):1612–31.

Yucel T, Cebe P, Kaplan DL. Vortex-Induced Injectable Silk Fibroin Hydrogels. Biophysical Journal. 2009 Oct;97(7):2044–50.

Product Certificate of Analysis

No result for .

Product Disclaimer

This product is for R&D use only and is not intended for human or other uses. Please consult the Material Safety Data Sheet for information regarding hazards and safe handling practices.