-

Collagen

-

Type I - Atelocollagen

- PureCol® Solution, 3 mg/ml (bovine) #5005

- Nutragen® Solution, 6 mg/ml (bovine) #5010

- FibriCol® Solution, 10 mg/ml (bovine) #5133

- PureCol® EZ Gel, Solution, 5 mg/ml (bovine) #5074

- PureCol® Lyophilized, 15 mg (bovine) #5006

- VitroCol® Solution, 3 mg/ml (human) #5007

- VitroCol® Lyophilized, 15 mg (human) #5008

-

Type I - Telocollagen

- TeloCol®-3 Solution, 3 mg/ml (bovine) #5026

- TeloCol®-6 Solution, 6 mg/ml (bovine) #5225

- TeloCol®-10 Solution, 10 mg/ml (bovine) #5226

- RatCol™ for 2D and 3D, Solution, 4 mg/ml (rat) #5153

- RatCol™ High Concentration, Solution, 10 mg/ml (rat)

- RatCol™ lyophilized, 100 mg (rat)

- RatCol™ for Coatings, Solution, 4 mg/ml (rat) #5056

- Type I - Insoluble Collagen

- Type I - Bioinks

- Type II Collagen

- Type III Collagen

- Type IV Collagen

- Collagen Standard

-

PureCol® Collagen Coated Plates

- Collagen Coated T-25 Flasks #5029

- Collagen Coated 6-well Plates #5073

- Collagen Coated 12-well Plates #5439

- Collagen Coated 24-well Plates #5440

- Collagen Coated 48-well Plates #5181

- Collagen Coated 96-well Plates #5072

- Collagen Coated 384-well Plates #5380-5EA

- Collagen Coated 100 x 20 mm Dishes #5028

- MatTek Glass-Bottom Dishes

- MatTek Multi-Well Plates

- Collagen Scaffolds

- Collagen Hybridizing Peptides

-

Type I - Atelocollagen

- Tunable Stiffness

- CytoSoft™ Rigidity Plates

-

Bioprinting

- Support Slurry for FRESH Bioprinting

-

Bioinks for Extrusion Bioprinting

- Lifeink® 200 Collagen Bioink (35 mg/ml) #5278

- Lifeink® 220 Collagen Bioink (70 mg/ml) #5343

- Lifeink® 240 Acidic Collagen Bioink (35 mg/ml) #5267

- Lifeink® 260 Acidic Collagen Bioink (70 mg/ml) #5358

- GelMA Bioink

- GelMA A Bioink

- GelMA C Bioink

- Pluronic F-127 40% Sterile Solution

- GelMA 20% Sterile Solution

- Alginate 5% Sterile Solution

- Photoinitiators

- Bioinks for BIONOVA X

- Bioinks for Lumen X

- DLP Printing Consumables

-

Create Your Own Bioinks

- PhotoCol® Methacrylated Collagen

- PhotoGel® Methacrylated Gelatin 95% DS

- PhotoGel® Methacrylated Gelatin 50% DS

- PhotoHA®-Stiff Methacrylated Hyaluronic Acid

- PhotoHA®-Soft Methacrylated Hyaluronic Acid

- PhotoAlginate® Methacrylated Alginate

- PhotoDextran® Methacrylated Dextran

- PEGDA (Various Molecular Weights)

- Silk Fibroin, Solution

- PhotoSericin® Methacrylated Sericin

- Bioprinters

-

3D Hydrogels

- Thermoreversible Hydrogel

- Silk Fibroin

-

Type I Collagen for 3D Hydrogels

- PureCol® Solution, 3 mg/ml (bovine) #5005

- Nutragen® Solution, 6 mg/ml (bovine) #5010

- FibriCol® Solution, 10 mg/ml (bovine) #5133

- PureCol® EZ Gel, Solution, 5 mg/ml (bovine) #5074

- VitroCol® Solution, 3 mg/ml (human) #5007

- TeloCol®-3 Solution, 3 mg/ml (bovine) #5026

- TeloCol®-6 Solution, 6 mg/ml (bovine) #5225

- TeloCol®-10 Solution, 10 mg/ml (bovine) #5226

- RatCol® for 3D gels, Solution, 4 mg/ml (rat) #5153

- HyStem® Thiolated Hyaluronic Acid

- Methacrylated Collagen

- Methacrylated Gelatin

- Methacrylated Hyaluronic Acid

- Diacrylates

- Collagen Sponges

- Methacrylated Polysaccharides

- Spheroids and Organoids

- Extracellular Matrices

- HyStem / Hyaluronic Acid

-

Adhesion Peptides / Proteins

-

Recombinant Adhesion Proteins

- CD2, 0.5 mg/ml #5086

- CDH3, 0.5 mg/ml #5124

- CDH13, 0.5 mg/ml #5125

- CD14, 0.5 mg/ml #5089

- CDH18, 0.5 mg/ml #5090

- CD40, 0.5 mg/ml #5093

- CD86, 0.5 mg/ml #5096

- CD164, 0.5 mg/ml #5100

- CD270, 0.5 mg/ml #5127

- CD274, 0.5 mg/ml #5126

- CD276, 0.5 mg/ml #5123

- E-Cadherin (CD324), 0.5 mg/ml #5085

- ICAM2, 0.5 mg/ml #5107

- Adhesion Peptides

- Collagen Hybridizing Peptides

-

Recombinant Adhesion Proteins

- Reagents

- Assays

PhotoHA™-INK (Stiff)

Methacrylated Hyaluronic Acid (HAMA)

Catalog #D16110025362

PhotoHA™-INK (Stiff)

Methacrylated Hyaluronic Acid (HAMA)

Catalog #D16110025362

PhotoHA™-INK (stiff) is 5 mL of a 4% solution of methacrylated hyaluronic acid (HAMA) in PBS with 0.5% LAP, and forms stronger hydrogels than the PhotoHA-INK (soft), which is a GM-HA. This Ink is pre-formulated and ready for printing in the BIONOVA X.

Product Description

Advanced BioMatrix offers PhotoHA™-INK, a methacrylated hyaluronic acid (HAMA) ink with LAP for bioprinting with the BIONOVA X.

Hyaluronic acid is the most abundant glycosaminoglycan in the body being an important component of several tissues throughout the body. While it is abundant in extracellular matrices, hyaluronic acid also contributes to tissue hydrodynamics, movement and proliferation of cells, and participates in a number of cell surface receptor interactions.

For the majority of cell types, it is recommended to add additional ECM proteins to the hyaluronic acid hydrogels. The proteins provide important cell binding sites.

Product Q & A

Yes. There are quite a few publications citing various hyaluronidase protocols for digesting PhotoHA hydrogels. Here are a few:

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5460858/

The HA we use comes from biotechnological production, where the hyaluronic acid is extracted from the cell walls of the bacteria Streptococcus zooepidemicus.

The top represents PhotoHA-Stiff (HAMA). The bottom represents PhotoHA-Soft (GMHA).

.png)

.png)

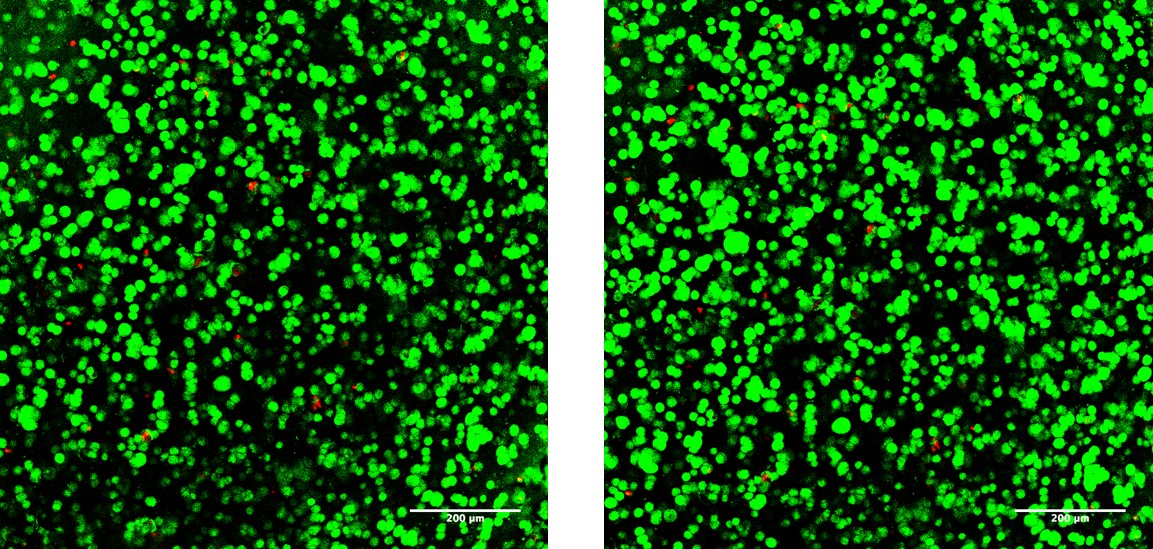

Product Cell Assay

Human mesenchymal stem cells (20 x 106 / mL) were encapsulated in 50 μL hydrogels (~ 4.7 mm x 2 mm). Hydrogels (1 wt% PhotoHA®) were fabricated with 0.05 wt% Irgacure 2959 and exposure to 2 mW/cm2 light (320-390 nm) for 10 minutes. After 24 hours, encapsulated cells were stained with calcein AM and ethidium homodimer and subsequently imaged on a Leica SP5 confocal microscope (using FITC/TRITC sequential scans).

Product Applications

Read our PhotoHA-Stiff Rheology Photocrosslinking White Paper here.

Read our Methacrylated Extracellular Matrices eBrochure Here

PhotoHA™ Methacrylated Hyaluronic acid can be used to form hydrogels for ex-vivo engineering of autologous cartilage tissue[1] or as a mesenchymal stem cell carrier in cartilage repair[2].

Because the stiffness can be widely adjusted by altering concentration or UV-light exposure, methacrylated HA has been used to measure the effects of matrix stiffness on cell phenotype and function[3][4].

Methacrylated HA can be used for 3D bioprinting (extrusion[5], inkjet[5] and photolithographic[6]) to create structures that promote osteogenic differentiation of MSC’s[7].

The high tunability of hyaluronic acid methacrylate allows it to be mixed with, and reinforce other types of hydrogels (such as collagen, or gelatin methacrylate)[8].

References:

Product References

References for PhotoHA®:

Khetan, Sudhir, and Owen Corey. "Maintenance of stem cell viability and differentiation potential following cryopreservation within 3-dimensional hyaluronic acid hydrogels." Cryobiology(2019).

Poldervaart, M. T. et al. 3D bioprinting of methacrylated hyaluronic acid (MeHA) hydrogel with intrinsic osteogenicity. Plos One12,(2017).

Product Certificate of Analysis

No result for .

Product Disclaimer

This product is for R&D use only and is not intended for human or other uses. Please consult the Material Safety Data Sheet for information regarding hazards and safe handling practices.