3D Bioprinting Bioglass and Collagen

05/18/20

The purpose of this study was to evaluate the printability of Bioglass mixed with Lifeink® 200 collagen bioink.

The bioglass creates a bioactive environment to promote hydroxyapatite formation and osteoblast bone secretion.

60% bioglass/40% collagen is the desired concentration, in order to best match the physiological ratios of inorganic/organic materials found in vivo.

This work was done in collaboration with Dr. Vipuil Kishore and his graduate student Mr. Nilabh Kajave from the Functional Biomaterials and Tissue Engineering Laboratory at Florida Institute of Technology.

Lifeink® 200 is a 35 mg/ml type I collagen bioink that was mixed with bioglass to perform this 3D bioprinting study. You can also view our Bioprinting eBrochure.

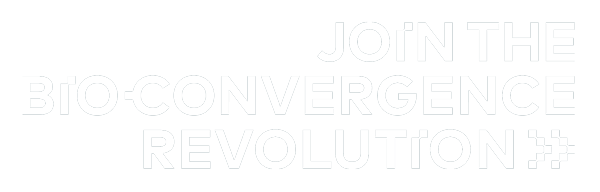

Alizarin Red S Staining

Alizarin Red S staining was performed on Lifeink® 200 collagen filaments that had been extruded through a 30 gauge needle into 1X PBS. The filaments had 0, 10, or 60% wt/wt bioglass. Red stain confirms bioglass incorporation in the filaments.

Alignment of Bioprinted Collagen

Polarized microscopy was used to determine the amount of alignment evident in Lifeink® 200 extruded filaments. Lifeink® 200 was mixed with bioglass in different amounts (10 and 60% wt/wt bioglass) and extruded through a 30 gauge needle. The light blue color indicated aligned collagen fibers. Results indicate some partial collagen fiber alignment in the collagen/bioglass filaments.

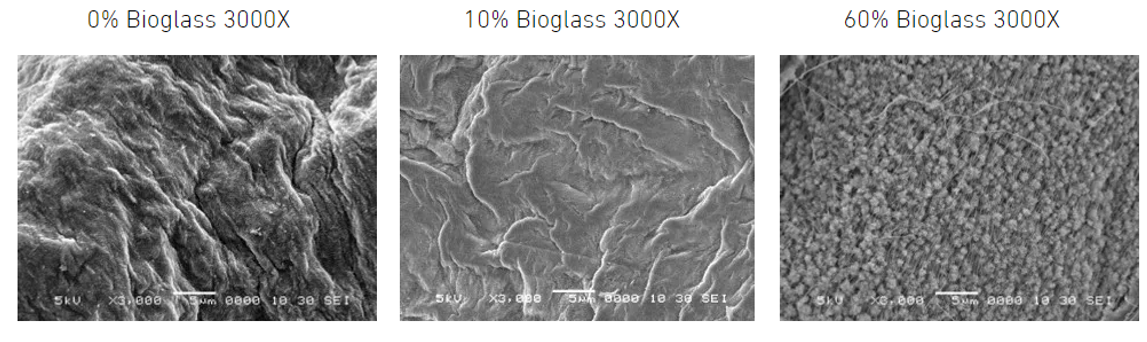

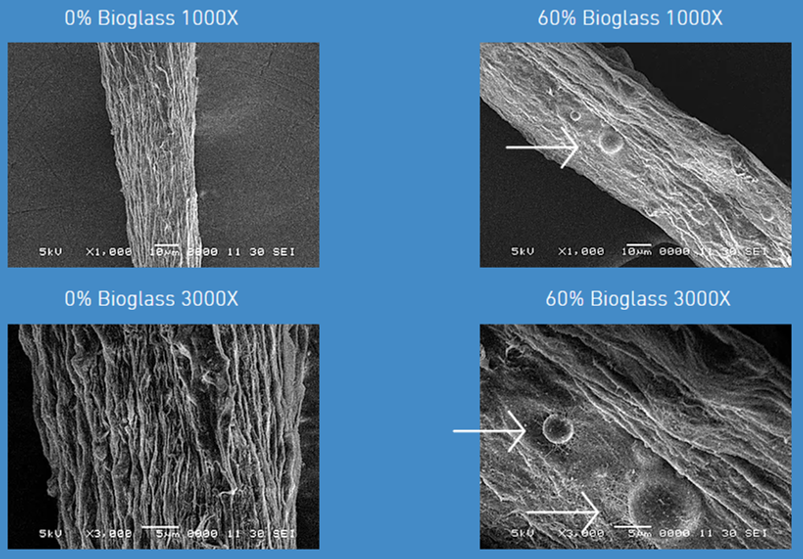

SEM Imaging for Bioglass Incorporation

SEM imaging was performed on Lifeink® 200 extruded filaments to confirm the presence of bioglass post-printing in the 60% wt/wt bioglass ink. Results show bioglass incorporated into the printed collagen filaments.

SEM Imaging - Hydroxyapatite Formation

SEM imaging was performed on Lifeink® 200 extruded filaments to confirm the formation of hydroxyapatite after 7 days incubation in simulated body fluids (SBF). Results show an evident layer of hydroxyapatite on the 60% wt/wt bioglass/collagen bioink extruded filaments.