Bioprinting

Basics of 3D Bioprinting

Bioprinting, a revolutionary technique in the field of regenerative medicine and tissue engineering, uses additive manufacturing technologies to create living tissue structures and ultimately enables a transition to 3D cell culture allowing researchers to better mimic the natural environment of cells, providing them with the architecture and biochemical cues necessary for their growth and function. With this a significant advancement in biofabrication field researchers have access to more realistic tissue models for drug testing, disease modeling and, potentially, organ replacement.

3D Bioprinting

Bioprinters come in many shapes, sizes and have different mechanisms of working. Here are the most common bioprinting modalities and how they work:

- Extrusion bioprinting: This method employs mechanical or pneumatic dispensing systems to deposit bioinks in a layer by layer manner building up a structure in three dimensions. Extrusion bioprinting allows for a great deal of versatility, especially in terms of materials and cell types used. Examples include the BIO X and BIO X6 from CELLINK.

- DLP-based bioprinting: This modality uses light, either in the visible or ultraviolet spectrum, to cure photosensitive bioinks into the desired 3D structure. Typically, DLP based printers project an image of layer into a photosensitive material, causing a chemical reaction and the fabrication of an entire layer. This mechanism provides users with high resolution and high speed printing capabilities. Examples include the LUMEN X and the BIONOVA X from CELLINK.

- Inkjet bioprinting: This is a non-contact type of bioprinting uses a piezo-electric system to deposit biomaterials in a drop by drop manner, allowing users to work with low viscosity materials, and develop micro-patterns. Examples include the EMD printhead which is used on the BIO X and BIO X6 from CELLINK.

- Two photon polymerization (2PP): This advanced technique uses a focused laser beam to polymerize a photosensitive material, allowing for the construction of complex 3D structures with extremely high spatial resolution. Examples include the Quantum X bio from CELLINK and Nanoscribe.

Other newer printing technology includes volumetric, holographic, and acoustic 3D bioprinting.

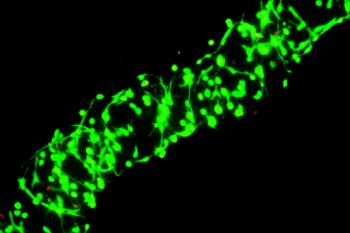

Lifeink® Collagen Bioinks

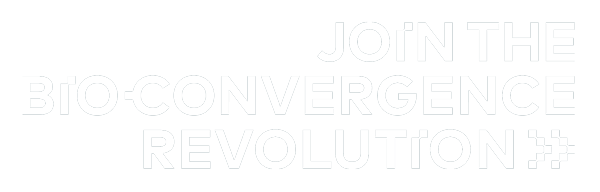

Lifeink® 200 and Lifeink® 240 are the world's first pure collagen bioinks for extrusion based 3D bioprinting. The human neonatal heart (right) was printed entirely out of Lifeink® 200 as seen in this publication.

Lifeink® 200 is a 35 mg/ml type I collagen that comes pH neutral and isotonic - ready for cell addition or immediate bioprinting.

Lifeink® 220 is a 70 mg/ml type I collagen that comes pH neutral and isotonic - ready for cell addition or immediate bioprinting.

Lifeink® 240 is a 35 mg/ml type I collagen that comes in an acidic pH, optimal for extremely high resolution bioprinting. Lifeink® 240 is neutralized immediately upon extrusion into the buffered LifeSupport® support bath (FRESH printing).

Lifeink® 260 is a 70 mg/ml type I collagen that comes in an acidic pH. Lifeink® 260 is neutralized immediately upon extrusion into the buffered LifeSupport® support bath (FRESH printing).

All of our Lifeink® products are optimal when printed using LifeSupport® for FRESH bioprinting.

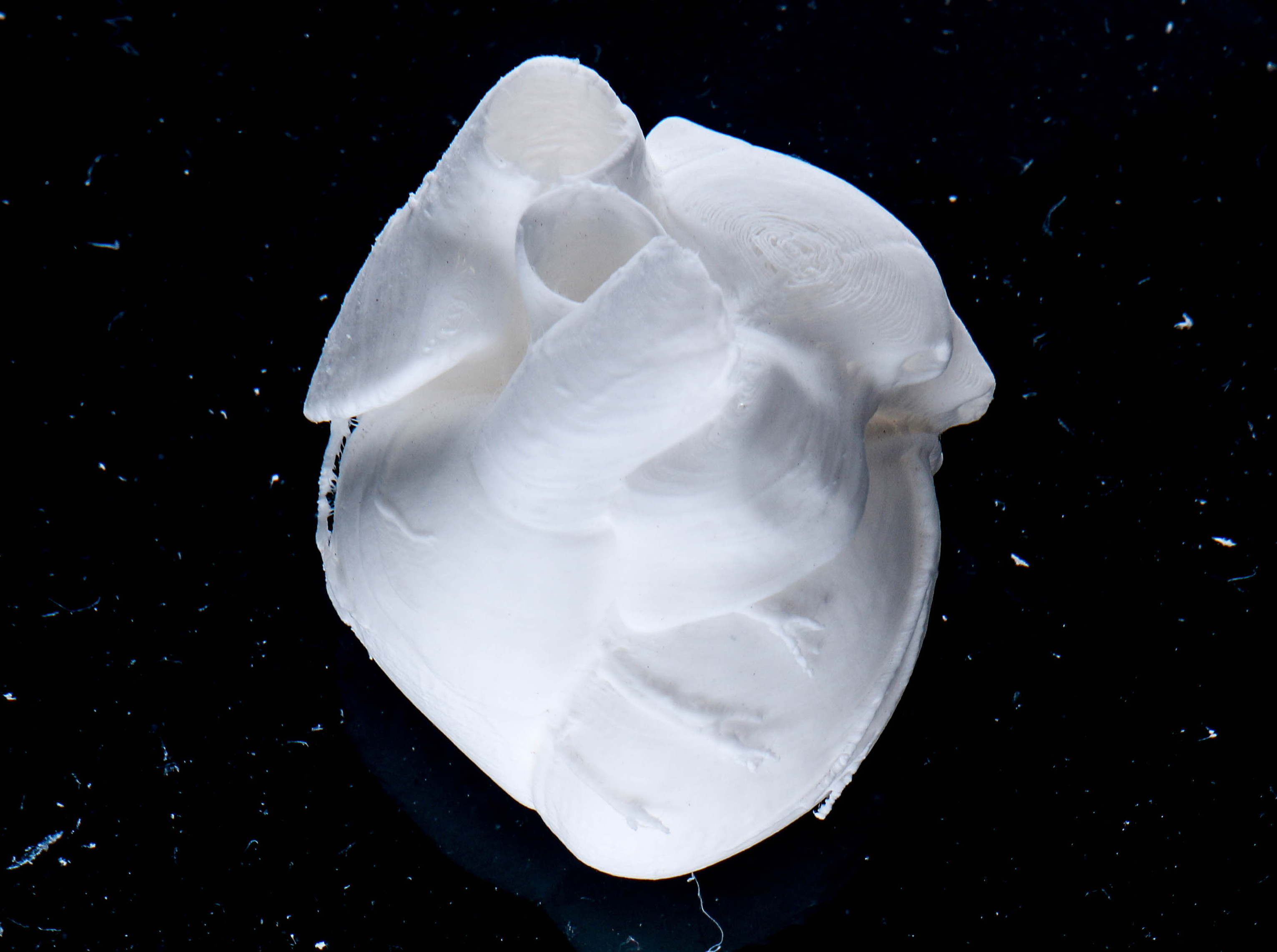

FRESH 3D Bioprinting

For extrusion based bioprinting, we recommend using the FRESH method. FRESH stands for Freeform Reversible Embedding of Suspended Hydrogels. The technology utilizes a gelatin support bath, or slurry, that essentially traps your construct in place as you print. You literally print directly inside the slurry, as seen to the right.

In order to print native extracellular matrix proteins without the use of added non-native materials (such as cellulose or alginate), a support material is required. Natural proteins lack rapid crosslinking or structural integrity for verticle 3D printing, without support.

LifeSupport® is the official ready-to-use gelatin support slurry for FRESH bioprinting and has been used to print amazing constructs, including nasal cartilage, a meniscus, heart valves and even an entire heart - out of native ECM proteins.

DLP Bioprinting Bioinks

Digital Light Processing (DLP) bioprinting, exemplified by technologies like the Lumen X and Bionova X from Cellink, represents a significant advancement in the field of tissue engineering. DLP printing uses high resolution light and photocrosslinking to rapidly create complex 3D structures.

Many of our light-based bioinks come preformulated with polymer and photoinitiator. These include ready-to-use inks using methacrylated gelatin, methacrylated hyaluronic acid, methacrylated alginate, and PEGDA.

We also provide specialty printing plates, probes, and VATs designed specifically for the Bionova X and Lumen X bioprinters. Check out a few of our inks for the BIONOVA X:

PhotoGel®-Ink 95%, PhotoGel®-Ink 50%, PhotoHA®-Stiff, PhotoHA®-Soft, PEGDA-Ink, PhotoAlginate®

Two-Photon Polymerization

Two-Photon Polymerization (2PP), also known as two-photon or multi-photon lithography or direct laser writing, is a key enabling technology for innovations in high-precision additive manufacturing with 3D printing and grayscale lithography systems. Print any 3D design with submicron features and sizes up to the centimeter range, with excellent shape accuracy and at the highest throughput.

Additive manufacturing by 3D printing enables design freedom not only at the macroscale, but also at the nano-, micro- and mesoscale. Two-Photon Polymerization (2PP) is the key technology for achieving this, based on the principle of two-photon absorption and providing a resolution 100 times higher than 3D printing technologies based on one-photon absorption, such as stereolithography (SLA), digital light processing (DLP), or projection microstereolithography (PµSL).

Quantum X bio - The world’s most accurate 3D bioprinter

The Quantum X bio is an exceptionally capable, versatile bioprinter with the highest resolution and accuracy available. Powered by Two-Photon Polymerization (2PP) and grounded in engineering excellence, the proprietary technology is customized and reimagined through the eyes of a biologist.

The light-based 3D bioprinter offers essential features such as precise temperature and humidity control, HEPA-filtered airflow and an optional connection for pre-mixed air/CO2. A variety of functionalized biomaterials can be used to unlock a new level of bioprinting and effectively accelerate innovation in tissue engineering, microbiology, materials engineering and biomedical devices.

Common materials printed with the Quantum X bio include:

PhotoGel®, PhotoHA®, PhotoDextran® and PhotoChitosan®.